To satisfy your quality requirements, SUCHIER applies a control and autocontrol policy: at each step of the manufacturing process. Our quality system is regularly audited and meets the ISO 9001 and AS9100 standards.

A 4 technician team works in 2 shifts and is distributed in 2 temperature controlled room (1 per site ) dedicated to the control in all its aspects and to the metrology.

Beyond the dimensional measurements, our technicians are familiar with:

- The documentary aspects : declaration of conformity and certificate of test reading and analysis (heat and surface treatments, mechanical tests, painting, non destructive controls), EN 9102 First Article Inspection and Industrial Substantiation Files realizations.

- The control of our suppliers’ special operations.

We meet your traceability issues: material, dimensional… for security articles and critical parts. To achieve it, we use a powerful ERP, a numerical document management and marking machines.

Some persons are authorized for sensitive programs with strong confidential requirements.

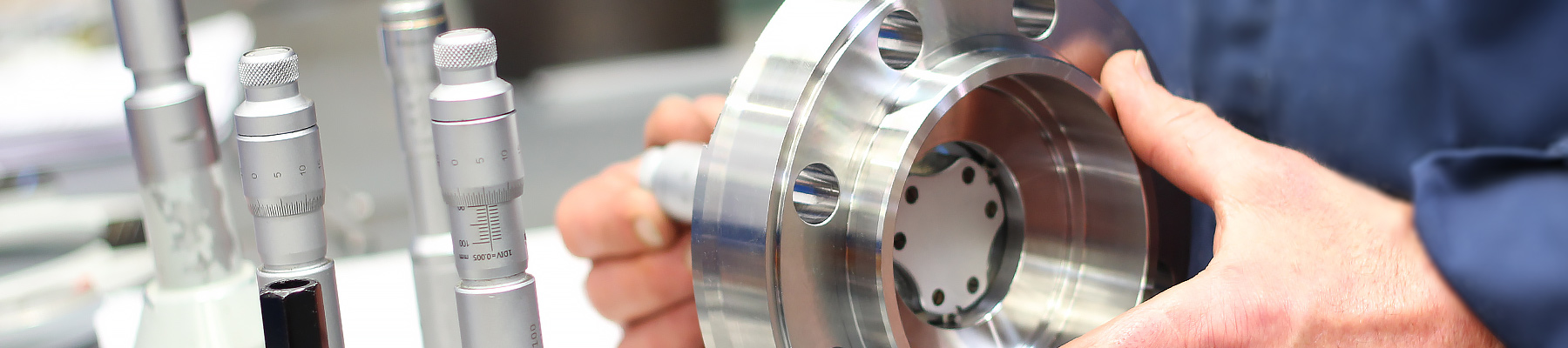

Inspection equipment

- 3 MITUTOYO CNC Coordinate Measuring Machine ( up to 900×1000×600mm ) with scanning possibilities.

- Hardness testing machine

- 3 measuring columns

- Profile projector

- Surface roughness tester

- Extensive set of pins and rings, threaded or not.

- Extensive set of micrometers up to 600 mm

- Coating thickness measuring system

Our inspection equipments are directly managed by our ERP and are regularly calibrated by an external certified organization.

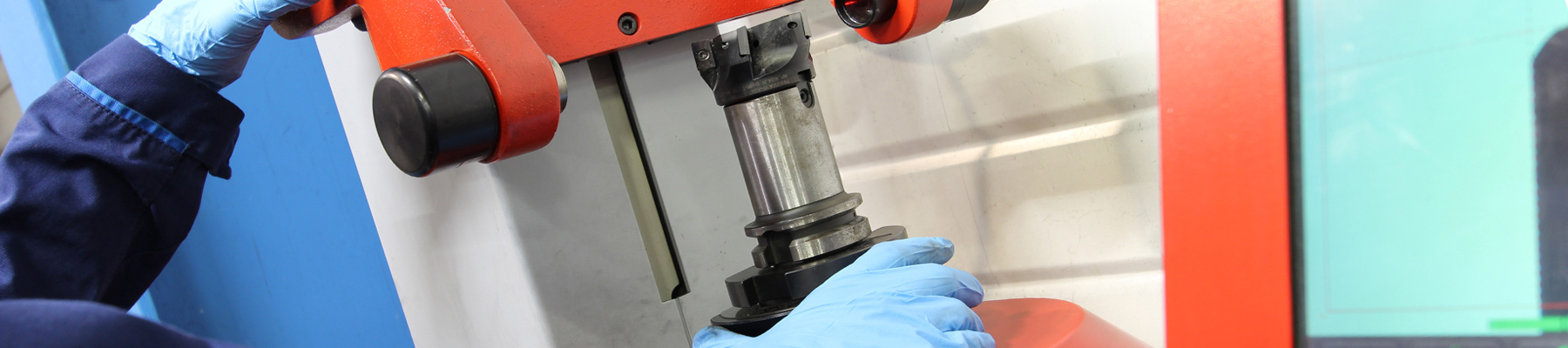

Marking equipment

- 4 machines: micro percussion, engraving, ink, laser